electric double seat control valve

technical parameter

item model number: zazn

nominal diameter: dn20~300mm

nominal pressure: pn1.6~6.4mpa

working temperature: -40~230℃ (normal temperature type), 230~450℃ for heat sink type (medium temperature type),

-100~600℃ for special order

main material: wcb(zg230-450), zg1cr18ni9ti, zg0cr18ni12mo2ti cf8 cf8m

applicable medium: liquid, gas, steam, etc.

flange size: in line with jb78-59, jb79-59 standards, according to jb/79.1-94, jb, ansi, jis, din and other standards

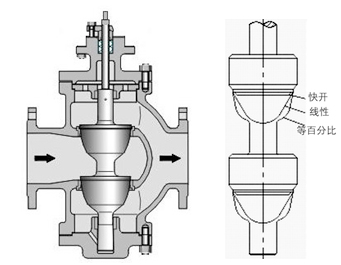

product description

the electric double-seat regulating valve is composed of dkz-type direct-range electric actuator and straight-through low-flow resistance double-seat valve. the double-seat double-guided structure makes the valve core stable and reliable during the displacement process. there are two valve seats and two columns in the valve body. the plug-shaped valve core, the fluid medium flows out through the upper and lower valve core valve seats, with large flow rate, large allowable pressure difference, and small unbalanced force. it is a balanced structure double seat valve, suitable for medium and leakage requirements that are not very clean. not strict occasions. it is widely used in automatic adjustment and remote control of industrial production processes such as chemical, petroleum, metallurgy, power plants, light textiles, papermaking and pharmaceuticals.

main technical parameters of the actuator

| model | dkz-310/310c | dkz-410/410c | dkz-510/510c | |||||||||

| thrust n | 4000 | 6400 | 16000 | |||||||||

| route | 10 | 16 | 25 | 30 | 18 | 30 | 40 | 60 | 30 | 50 | 60 | 100 |

| full travel time s | 8 | 12.5 | 20 | 24 | 15 | 24 | 32 | 48 | 16 | 30 | 37 | 62 |

| project | index | |

| basic error % | ≤±5.0 | |

| return difference % | ≤3.0 | |

| dead zone% | ≤3.0 | |

| leakage | double seat valve | 10-3×valve rated capacity |

| double seat valvedouble seat valve | 10-3×valve rated capacity | |

allowable differential pressure

| usage | the valve core is in the open state, when the valve is closed, the pressure behind the valve is p2=0 | ||||||||||

| dn(mm) | seat diameterdn(mm) | executive body effective thrust (n) | allowable differential pressure(mpa) | ||||||||

| pn1.6(mpa) | pn6.4(mpa) | ||||||||||

| 20 | 10 | 12 | 15 | 20 | 400,1000,2500 | pn | 3.8 | 2.7 | 1.7 | 1.0 | |

| pn | 4.3 | 2.5 | |||||||||

| 25 | 26 | 400,1000,2500 | 0.5 | pn | 0.6 | 3.6 | |||||

| 32 | 32 | 0.4 | pn | 0.4 | 2.3 | ||||||

| 40 | 40 | 400,1000 2500,6400 | 0.7 | 1.0 | 0.7 | 1.5 | |||||

| 50 | 50 | 0.5 | 1.0 | 0.5 | 1.0 | ||||||

| 65 | 66 | 6400,16000 | 1.4 | 1.4 | |||||||

| 80 | 80 | 1.0 | 1.0 | ||||||||

| 100 | 100 | 0.6 | 0.6 | ||||||||

| 125 | 125 | 6400,16000 | 0.5 | 1.0 | 0.5 | 1.0 | |||||

| 150 | 150 | 0.3 | 0.7 | 0.3 | 0.7 | ||||||

| 200 | 200 | 0.2 | 0.4 | 0.2 | 0.4 | ||||||

| 250 | 250 | 16000 | 0.3 | 0.3 | |||||||

| 300 | 300 | 0.2 | 0.2 | ||||||||

material of main parts and applicable temperature and medium

| material code | c(wcb) | p(304) | r(316) | |

| main part | body, bonnet | wcb(zg230-450) | zg1cr18ni9ti(304) | zg1cr18ni12mo2ti(316) |

| valve core, seat | 1cr18ni9ti(304)or stellite surfacing welding | 1cr18ni9ti(304)stellite surfacing welding | 1cr18ni12mo2ti(316) or stellite surfacing welding | |

| stem | 2cr13 | 1cr18ni9ti | 1cr18ni12mo2ti | |

| filler | v-type ptfe (f4), flexible graphite, stainless steel bellows | |||

| gasket | reinforced polytetrafluoroethylene (f4), stainless steel gasket, metal graphite spiral wound gasket | |||

| push rod, bushing | 2cr13 | |||

| applicable working conditions | applicable media | water vapor oil gas liquid | nitrate alkali corrosive gas and liquid | corrosive gases and liquids such as acetic acid |

| normal temperature | -30~ 250 f4:≤200℃ | -40~ 250 f4:≤200℃ | -40~ 250℃ f4:≤200℃ | |

| high temperature | -30~ 450℃ | -40~ 450℃ | -40~ 450℃ | |

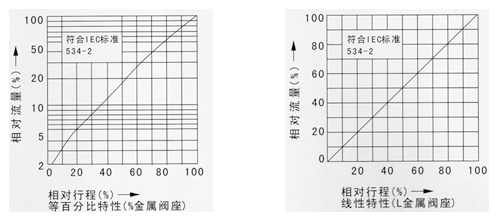

flow characteristics diagram

the main technical parameters

| dn mm | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | |||

| seat diameter mm | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | |||

kv | two-seater | 10 | 16 | 25 | 40 | 63 | 100 | 160 | 250 | 400 | 630 | 1000 | 1600 | |||

| sleeve | full amount | 15 | 35 | 50 | 125 | 190 | 400 | 630 | ||||||||

| 0.6 | 9 | 20 | 30 | 75 | 115 | 240 | 350 | |||||||||

| rated stroke l(mm) | 10 | 16 | 25 | 40 | 60 | 100 | ||||||||||

| actuator model | dkz-310 | dkz-310 | dkz-310 | dkz-410 | dkz-410/510 | dkz-510 | ||||||||||

| shaft thrust n.m | 4000 | 4000 | 4000 | 6400 | 6400/16000 | 16000 | ||||||||||

| full travel time s | 8 | 12.5 | 20 | 32 | 48/37 | 62 | ||||||||||

| voltage | ac220v 50hz | |||||||||||||||

| input signal | 4~20ma dc 0~10ma dc | |||||||||||||||

| input resistance | type ii: 200ω type iii: 250ω | |||||||||||||||

| mode of action | electric open type (k) type, electric close type (b) type | |||||||||||||||

| flow characteristics | equal percentage, straight line, quick opening | |||||||||||||||

| allowable leakage(l/h) | double seat≤10-3×rated capacity;sleeve:≤10-3×rated capacity of valve | |||||||||||||||

| inherent turndown ratio r | 30:1 | |||||||||||||||

| pn(mpa) | 1.6 2.5 4.0 6.4 | |||||||||||||||

main external connection dimensions

| dn | a×b | l | h | h1 | ||||

| zazn two-seater | ||||||||

| pn1.6 | pn4.0 | pn6.4 | normal type | hot plate type | zazp | zazn | ||

| 20 | 230×460 | 180 | 185 | 190 | / | / | 91 | / |

| 25 | 185 | 190 | 205 | 670 | 820 | 112 | 104 | |

| 32 | 200 | 210 | 220 | 673 | 823 | 118 | 107 | |

| 40 | 220 | 230 | 240 | 693 | 843 | 129 | 126 | |

| 50 | 250 | 255 | 265 | 698 | 848 | 144 | 131 | |

| 65 | 230×530 | 275 | 285 | 295 | 799 | 959 | 175 | 175 |

| 80 | 305 | 310 | 325 | 809 | 969 | 191 | 190 | |

| 100 | 350 | 355 | 370 | 821 | 981 | 195 | 202 | |

| 125 | 260×630 | 410 | 425 | 440 | 872 | 1087 | 243 | 250 |

| 150 | 450 | 460 | 475 | 882 | 1097 | 251 | 260 | |

| 200 | 550 | 560 | 570 | 924 | 1139 | 290 | 302 | |

| 250 | 670 | 690 | 750 | 1156 | 1368 | 380 | 422 | |

| 300 | 740 | 785 | 815 | 1215 | 1427 | 435 | 484 | |